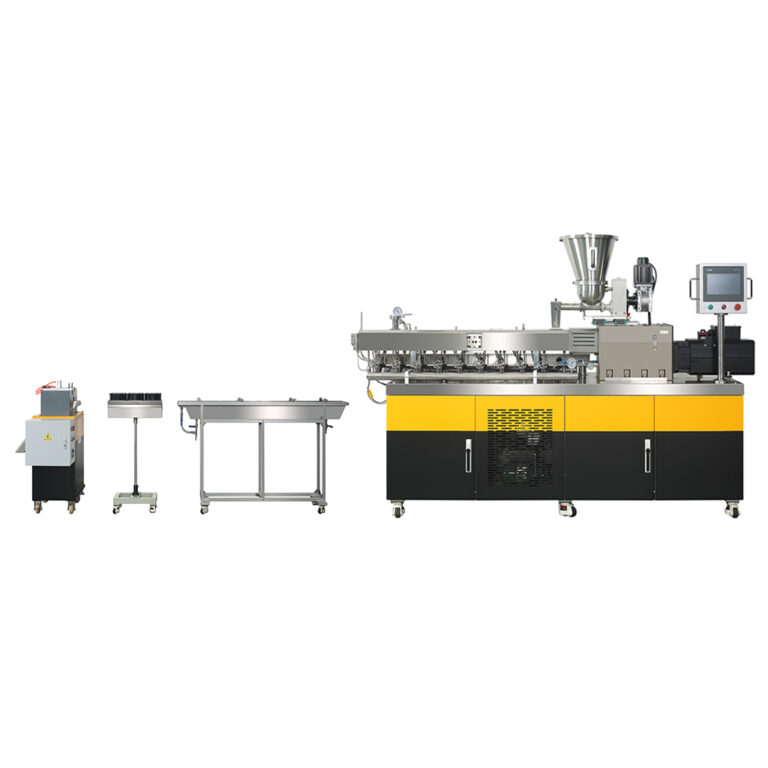

Product Introduction:

Twin-screw water strand pelletizer is a kind of equipment used for plastic processing, especially suitable for water strand pelletizing process, suitable for processing a variety of plastic materials, including but not limited to PE, PP, PA, PS, ABS, PET, PC, TPR, TPV, etc. The main working process of this equipment includes high mixer, spiral automatic feeder, twin-screw pelletizer, cooling water tank, blow dryer and pelletizing. Twin-screw pelletizer can have various pelletizing methods for different materials, including air-cooled die face hot cutting, water strand pelletizing, conveyor belt pelletizing, water ring pelletizing, eccentric water mist pelletizing and underwater pelletizing.

Product performance:

1. High-efficiency production capacity: The equipment adopts side feeding technology to improve the integrity of the material, thereby greatly increasing the output. The position and shape of the feed port have a significant impact on the feeding efficiency. Through optimized design, higher output can be achieved under the same parameters.

2. Good material adaptability: The twin-screw granulator has strong self-cleaning ability and can adapt to different types of materials. By increasing the number of kneading blocks, the number of kneading can be increased, the kneading quality can be improved, and various processing needs can be met.

3. Energy saving and environmental protection: The equipment adopts advanced co-rotating twin-screw granulator technology to achieve equal gap meshing, improve the self-control performance and processing capacity of the screw, and at the same time broaden its application field, with strong adaptability and able to meet the needs of different materials.