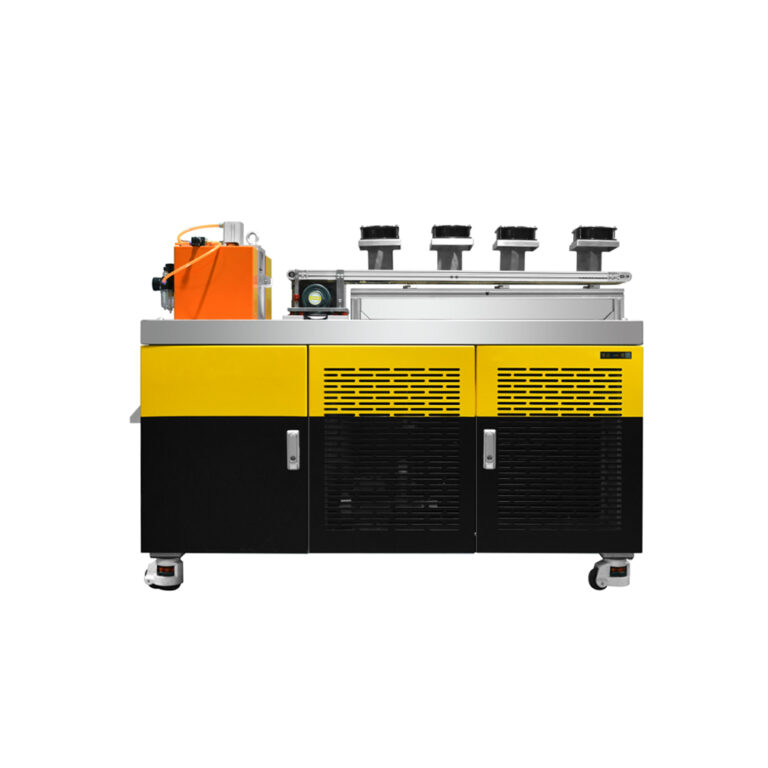

Product Introduction:

The two-in-one strand cooling granulation auxiliary machine is a plastic granulation equipment that combines stranding and cooling processes to process plastic materials into granules. It is suitable for a variety of plastic granulation applications, including but not limited to plastic filling modification, reinforced plastics, masterbatch, engineering plastic alloys, special masterbatch, etc. The main feature of this auxiliary machine is that it combines the stranding and cooling processes, thereby improving production efficiency and simplifying the operation process.

Product performance:

1. Efficient cooling: The equipment adopts an advanced cooling system, which can quickly and effectively reduce the material temperature and ensure the stability and uniformity of the material during the granulation process.

2. Energy saving and environmental protection: It adopts an environmentally friendly wind cooling system, and does not need to be connected to external circulating water cooling, which avoids the waste of water resources, and also reduces the problem of wastewater treatment, meeting environmental protection requirements.

3. Structural optimization: The equipment structure is reasonably designed and can adapt to different production needs and improve production efficiency.

4. Strong durability: Key components such as barrels and screws are made of high-quality nitrided steel. After gas nitriding treatment, they have good mechanical properties such as high hardness, wear resistance and corrosion resistance, which prolongs the service life of the equipment.

5. Easy maintenance: The heating system of the equipment adopts a cast copper heater, and the outer cover is a stainless steel wind cover, which is beautiful and energy-saving, has good heat resistance, long service life, uniform heat transfer, and easy replacement.